Auto Centering Vibrating Screen

Auto Centering Vibrating Screen is to solve the wet viscous material depth screening equipment, especially for less than 10mm wet sticky coal screening.

Production capacity : 1-300t/h

Scope of Application : Apply to mining, metallurgy, building materials, chemical industry and other departments for granular materials in the classification

Structure

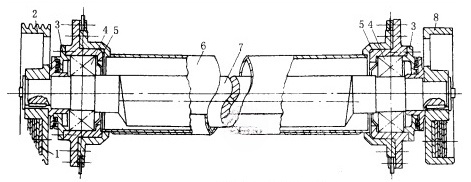

1. Mining Self-fixed centre shale shaker is composed of sealing cover, screen box, sieve plate, dust removing mouth, exciter, soft connecting device and damping spring.

2. Mining Self-fixed centre shale shaker is the use of large amplitude, large vibration intensity, low vibration frequency and self-cleaning screen surface to complete wet viscous material screening process.

3. Mining Self-fixed centre shale shaker is not an integral part of the vibration, the screen machine side panels, roof, base is a fixed part, only the sieve plate and exciter assembly to participate in vibration.

4. Mining Self-fixed centre shale shaker is a special steel bar and frame composition, the bars were arranged vertically, the whole screen in the vibration, at the same time each bar there is also an active gap, and do secondary vibration, to maximize the elimination of wet sticky raw coal on the screen of the bonding problem.

Advantages

1. Mining Self-fixed centre shale shaker used in coal-fired power plants, are generally made of closed structure, so that dust cannot be leaked, to respond to environmental requirements.

2. Mining Self-fixed centre shale shaker with the sieve body without vibration and sieve plate vibration process characteristics, with higher amplitude, lower dynamic load advantages.

3. Mining Self-fixed centre shale shaker with fewer moving parts, vibration quality is small, so its power can be reduced to a minimum. Compared with the traditional screen machine, can reduce the power more than doubled.

4. Mining Self-fixed centre shale shaker is generally used 1-6 sets of motor drive, each motor starting time interval of 6-8 seconds. Sieve machine without material more conducive to observation and maintenance.

5. Mining Self-fixed centre shale shaker with modular, standardized components, so that the overall rapid replacement, greatly reducing on-line maintenance time.

6. Exciter end and the connection parts are equipped with protective devices, safe operation.

7. Better to solve the problem of screen plugging, high screening efficiency.

Parameter

| Self-fixed centre shale shaker | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Specification | Max particle(mm) | Production capacity (t/h) | Motor | weight(kg) | Note | |||||

| Model | Power(kw) | ||||||||||

| SZZ0918 | 900×1800 | 40 | 20~25 | Y100L1-4 | 2.2 | 420 | Hanging-type | ||||

| SZZ0918 | 553 | Seating- type | |||||||||

| 2SZZ0918 | 570 | Seating- type | |||||||||

| SZZ1225 | 1250×2500 | 100 | 100 | Y132S-4 | 5.5 | 1020 | Hanging-type | ||||

| SZZ1225 | 1330 | Seating- type | |||||||||

| 2SZZ1225 | 1320 | Hanging-type | |||||||||

| 2SZZ1225 | 1335 | Seating- type | |||||||||

| SZZ1530 | 1500×3000 | 200 | Y132M-4 | 7.5 | 1650 | Hanging-type | |||||

| SZZ1530 | 1700 | Seating- type | |||||||||

| 2SZZ1530 | 2870 | Hanging-type | |||||||||

| SZZ1540 | 1500×4000 | 100 | 90-200 | Y160L-4 | 15 | 3412 | Seating- type | ||||

| 2SZZ1540 | 1500×4000 | 100 | 250 | Y160L-4 | 15 | 4240 | Seating- type | ||||

| 2SZZ1540 | 1500×4000 | 100 | 250 | Y160L-4 | 15 | 4240 | Seating- type | ||||

| SZZ1836 | 1800×3600 | 150 | 300 | Y180M-4 | 18.5 | 4500 | Hanging-type | ||||

| 2SZZ1836 | 5616 | Seating- type | |||||||||