Next

High-efficiency reformed thickener

Compared with the ordinary thickener, efficient thickener have a large production capacity (processing capacity can be increased several times).

Application material : Material, coal slime, waste water, waste residue, etc

Scope of Application : Metallurgy, mining, coal, chemical industry, building materials, environmental protection and other departments

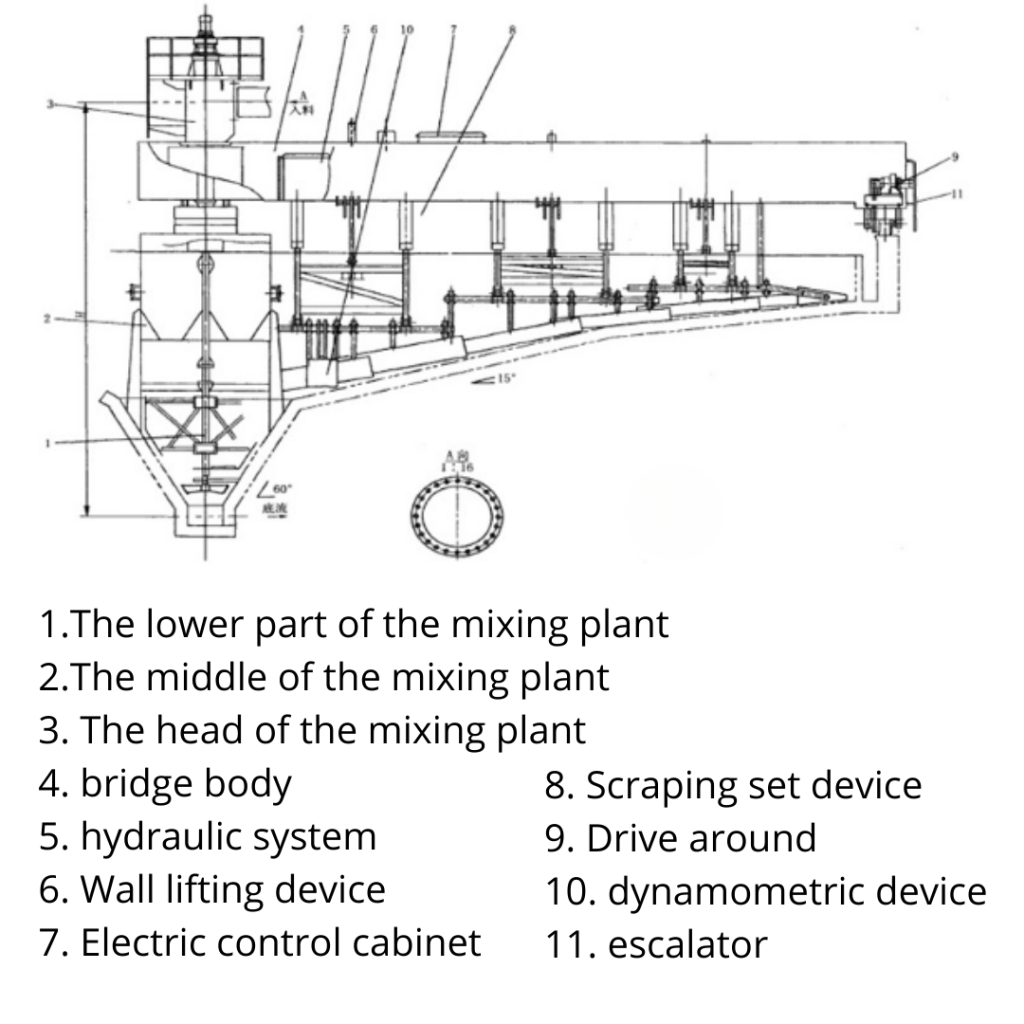

Structure

The vertical axis rotates driven by motor, and pulp by feeding device flows into the tank center feed mixing barrel.Solid material in the bottom of the tank by the scraper moves out of center; clarified overflow through the tranquil flow device flows out from the ring external overflow weir.

Advantages

Out overflow weir instead of inner overflow weir increases the sedimentation area and not easy to block.

Oblique feeding instead of horizontal feeding solves the blockage problem.

A tranquil flow device reduces material flow rate, so that the overflow becomes more uniform with lower turbidity.

Parameter

| High-efficiency reformed thickener | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | thickening pond | Deposit area(m2) | Motor | Production capacity(t/d) | Tank weight(kg) | gross weight(kg) | |||

| diameter(m) | depth(m) | Model | Power(kw) | ||||||

| NZSG2.5 | 2.5 | 1.8 | 4.9 | Y90L-6 | 1.1 | 5-22.4 | 1095 | 2355 | |

| NZSG3 | 3 | 1.8 | 7 | Y100L-6 | 1.5 | 5-23.3 | 1633 | 3167 | |

| NZSG3.6 | 3.6 | 1.8 | 10.2 | Y100L-6 | 1.5 | 5-25 | 2097 | 3680 | |

| NZSG-5 | 5 | 2.956 | 16 | Y90L-4 | 1.5 | 16-90 | 5160 | 8031 | |

| NZSG-6 | 6 | 2.956 | 28.3 | Y90L-4 | 1.5 | 98 | 5769 | 9200 | |

| NZSG-7 | 7 | 3 | 38.5 | Y112M-6 | 2.2 | 140 | 8548 | 13361 | |

| NZSG-8 | 8 | 3 | 50.2 | Y132S-6 | 3 | 185 | 12966 | 19289 | |

| NZSG-9 | 9 | 3 | 63 | Y132S-6 | 3 | 210 | 15439 | 21960 | |

| NZSG-12 | 12 | 3.6 | 113 | Y132S-6 | 3 | 370 | 25589 | 34823 | |

| NZSG-15 | 15 | 3.6 | 176 | Y132M2-6 | 5.5 | 580 | 35800 | 58800 | |

| NZSG-18 | 18 | 3.74 | 255 | Y160M-6 | 7.5 | 960 | 51000 | 75600 | |

| NZSG-20 | 20 | 4.4 | 315 | Y160M2-8 | 7.5 | 1400 | 62000 | 83550 | |

| NZG-24 | 24 | 4.716 | 452 | Y180L-8 | 11 | ≥1400 | 83700 | 115840 | |