Next

NXZ High efficacious thickener

High-efficacious Thickeners are not only sedimentation equipments but also new type dehydrating equipments with the mash percolate features. By adding flocculating agent, bigger the diameter of the deposit solid grain, speed up the deposit. The High-efficacious Thickener is usually used after floatation separator when it is applied in beneficiation process.

Scope of Application : Chemical industry, coal, building materials and water and sewage treatment industries containing solid material in the enrichment and purification of serum

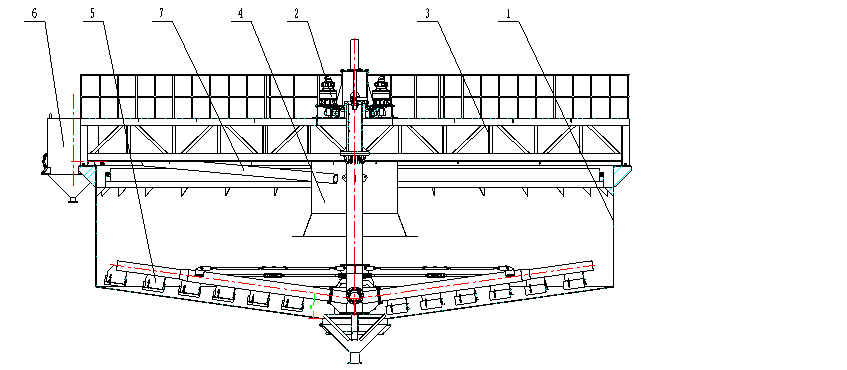

Structure

Application

Thickener is mainly used for slurry adjustment and dewatering treatment in mineral processing, and for dewatering operation in chemical industry, paper making and coal preparation plant.

working principle

Thickener is a solid-liquid separation equipment based on gravity settlement. It is usually a shallow cylindrical groove with conical bottom made of concrete or metal welded plates as structural materials. The slurry with solid weight of 10%-20% can be concentrated by gravity settling of the thickener to the bottom flow slurry with solid content of 45%-55%. The thickened bottom flow slurry can be discharged from the bottom flow outlet at the bottom of the thickener by means of the rake installed in the thickener with slow running (0.2-0.35r/min). The clarifier produced by concentration (overflow) is left in the upper part of the thickener and discharged by the annular chute at the top.

Concentration process: The pulp entering the pond gradually naturally forms five different zones. A clarification zone, B free subsidence zone, C sedimentation zone, D concentration zone and E slime zone. Concentration of pulp begins with free subsidence zone B, but the main process of concentration is in concentrate zone D.

Features

-

Shell

-

Hydraulic Driving Device

-

Summer beam

-

Flow stabilizer

-

Rake part

-

Degassing tank

-

Feeding pipe

Parameter

| NXZ High efficacious thickener | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| model | inner diameter | death | area | Production capacity | power | weight | |||

| NXZ-6 | Φ6 | 3100 | 28.27 | 50-100 | 3 | 5297 | |||

| NXZ-8 | Φ8 | 4762 | 50 | 100-200 | 7.5 | 16310 | |||

| NXZ-15 | Φ15 | 4510 | 176 | 260-400 | 7.5 | 24181 | |||

| NXZ-16 | Φ16 | 4545 | 200 | 400-600 | 5.5 | 28520 | |||

| NXZ-18 | Φ18 | 4545 | 254 | 650-900 | 5.5 | 30492 | |||

| NXZ-24 | Φ24 | 5343 | 450 | 1000-1500 | 7.5 | 38066 | |||

| NXZ-30 | Φ30 | 5343 | 706 | 1500-2000 | 7.5 | 46210 | |||

| NXZ-45 | Φ45 | 8033 | 1590 | 2400-3000 | 11 | 77200 | |||

| NXZ-53 | Φ53 | 6946 | 2206 | 3000-4000 | 15 | 99610 | |||

| NXZ-62 | Φ62 | 8439 | 3012 | 4500-8000 | 18.5 | 130100 | |||

| NXZ-80 | Φ80 | 9385 | 5025 | 8000-11000 | 22 | 1920360 | |||

| NXZ-100 | Φ100 | 8832 | 7658 | 15000-18000 | 30 | 2398500 | |||