Next

Single cylinder hydraulic cone crushers

My company independently researched and developed and designed this new type high efficient crusher depending on more than 20 years experience and widely absorbing advanced crusher technology such as the United States, Germany.The cone crusher set mechanical, hydraulic, electrical, automation and intelligent control technology at an organic whole which represent the world’s most advanced crusher technology .

Production capacity : 30-1000t/h

Application material : high hardness of rock material, such as: pebble, limestone, dolomite, granite

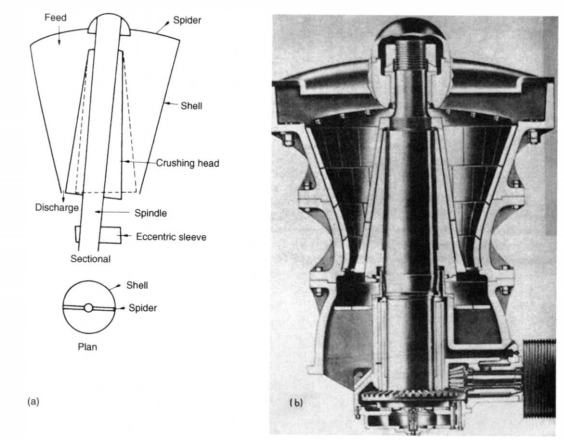

Structure

When Single-cylinder cone crusher working

motor drives the pinion of crusher and pinion drives gearwheel, gearwheel components (wheel, wheel frame, eccentric steel bushing) drives the eccentric set of components (eccentric eccentric cylinder liner, copper sets) and spindle components (main shaft, the inner cone, cone plate) for the center with theory of vertical line, orbit within the copper bushing, spindle component within the eccentric copper sleeve can be achieved with the center line of the spindle rotation.Empty when the chance that, eccentric sleeve components “hold” the spindle component and with big gear revolution, after the material into the crushing chamber, the spindle assembly (spindle, inner cone) under the resistance of the material in the eccentric copper set inside a slow rotation.Inner cone trajectory looks back and forth within the crushing cavity, slowly rotating at the same time.The material being swinging the inner cone of extrusion.Support and the frame body joint by the hydraulic cylinder pressure, falling into a metal piece inside the crusher not broken objects, such as single cylinder hydraulic piston in order to move from the bottom of the cone, the eliminator adjustment and iron protection, and eliminate the effect of blocking in over and over again.

Advantages

1, hydraulic regulating discharge mouth, combined with the humanized design, adjust the discharging mouth size using hydraulic adjustment, button control, save work and save trouble, and it can realize the infinite adjustment, adjust the high controllability.

2, single cylinder hydraulic regulating spindle, the cone integral lifting achieve the purpose of adjusting the discharging mouth size, and solve the damage of the rack on the side of the cylinder and tilts the host of problems.Hydraulic system automatically adjust the working pressure, crushing cavity inside will inevitably enter the super material crushing pressure, pressure regulating system, automatic start for pressure relief protection, automatic discharging mouth, let not broken through the discharging mouth machine, purpose of protection equipment.

3, easy attaint parts replacement fast, in order to save time in the replacement parts, after careful design and processing, combination between rolling mortar wall and cone surface joint is stable, reliable, and is no longer filling and filling supplements, saves each time in a strip and filling, and the installation of the rolling mortar wall, also saves filling material waste of money.

4, hydraulic pressure is low, the equipment of the hydraulic system working pressure is low (not high-pressure hydraulic system), the hydraulic parts and the host less pressure and hydraulic system more lasting stability, without fear of the hydraulic system.

5, installation convenient transportation, because this type of advanced design, high efficiency, are relatively small, the size and weight of hoisting, transportation and to change, with low maintenance requirements.

Parameter

| Hydraulic cone crusher(Superfine) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Type | Feeding size | Max particle | Min discharge size | Max discharge size | Motor power | weight | ||||

| stroke | stroke | stroke | stroke | stroke | stroke | ||||||

| PYY100 | 16 | 22 | 16 | 22 | 90 | 6000 | |||||

| A | 150 | 120 | 12 | 15 | 39 | 37 | |||||

| B | 130 | 105 | 10 | 11 | 16 | 22 | |||||

| C | 100 | 85 | 7 | 9 | 33 | 30 | |||||

| D | 40 | 32 | 5 | 6 | 31 | 29 | |||||

| PYY200 | 18 | 25 | 18 | 25 | 160 | 10600 | |||||

| A | 220 | 180 | 18 | 22 | 35 | 30 | |||||

| B | 150 | 120 | 15 | 19 | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | |||||

| D | 40 | 32 | 6 | 8 | 35 | 30 | |||||

| PYY300 | 25 | 32 | 25 | 32 | 250 | 15500 | |||||

| A | 230 | 190 | 20 | 25 | 45 | 40 | |||||

| B | 150 | 125 | 17 | 20 | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | |||||

| D | 40 | 32 | 6 | 8 | 40 | 35 | |||||

| PYY500 | 25 | 32 | 40 | 25 | 32 | 40 | 315 | 22500 | |||

| A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | |||

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | |||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | |||

| D | 50 | 40 | 8 | 10 | 12 | 30 | 25 | 20 | |||

| Model | Stroke | discharge size of pilled-in selvedge(mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 12 | 16 | 20 | 25 | 30 | 35 | 40 | 45 | ||

| PYY100 | 16 | 35-40 | 45-55 | 55-65 | 65-75 | 75-85 | 90-100 | 105-115 | ||

| 22 | 45-50 | 55-65 | 65-75 | 75-90 | 85-105 | 100-125 | 115-135 | |||

| PYY200 | 18 | 65-75 | 75-90 | 85-105 | 100-125 | 135-150 | 160-175 | 170-190 | ||

| 25 | 90-110 | 110-130 | 125-155 | 160-180 | 185-210 | |||||

| PYY300 | 25 | 100-120 | 110-135 | 130-160 | 150-180 | 170-200 | 200-230 | 230-260 | 250-290 | 270-310 |

| 32 | 110-135 | 130-150 | 160-200 | 180-220 | 200-250 | 230-280 | 260-310 | 280-320 | 300-340 | |

| PYY500 | 25 | 100-120 | 120-150 | 140-170 | 160-190 | 190-220 | 220-250 | 250-280 | 280-310 | 330-370 |

| 32 | 150-170 | 170-200 | 200-230 | 250-270 | 280-300 | 310-340 | 370-420 | 430-500 | ||

| 40 | 180-200 | 210-240 | 250-280 | 300-330 | 330-380 | 370-420 | 430-500 | |||

| Hydraulic cone crusher(Middle-sized) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Type | Feeding size | Max particle | Min discharge size | Max discharge size | Motor power | weight | ||||

| stroke | stroke | stroke | stroke | stroke | stroke | ||||||

| PYYZ100 | 16 | 22 | 16 | 22 | 90 | 6000 | |||||

| A | 150 | 120 | 12 | 15 | 39 | 37 | |||||

| B | 130 | 105 | 10 | 11 | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | 33 | 30 | |||||

| D | 40 | 32 | 5 | 6 | 31 | 29 | |||||

| PYYZ200 | 18 | 25 | 18 | 25 | 160 | 10600 | |||||

| A | 220 | 180 | 18 | 22 | 35 | 30 | |||||

| B | 150 | 120 | 15 | 19 | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | |||||

| D | 40 | 32 | 6 | 8 | 35 | 30 | |||||

| PYYZ300 | 25 | 32 | 25 | 32 | 250 | 15500 | |||||

| A | 230 | 190 | 20 | 25 | 45 | 40 | |||||

| B | 150 | 125 | 17 | 20 | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | |||||

| D | 40 | 32 | 6 | 8 | 40 | 35 | |||||

| PYY500 | 25 | 32 | 40 | 25 | 32 | 40 | 315 | 22500 | |||

| A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | |||

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | |||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | |||

| D | 50 | 40 | 8 | 10 | 12 | 30 | 25 | 20 | |||

| Model | Stroke | discharge size of pilled-in selvedge(mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | ||

| PYY100 | 16 | 135-150 | 145-160 | 155-175 | 165-185 | 175-190 | 180-205 | |||

| 22 | 160-180 | 170-200 | 180-210 | 190-220 | 200-230 | 205-230 | ||||

| PYY200 | 18 | 160-190 | 180-210 | 200-230 | 230-250 | 250-270 | 270-300 | |||

| 25 | 190-240 | 210-260 | 230-280 | 260-310 | 290-340 | 310-370 | ||||

| PYY300 | 25 | 250-300 | 290-340 | 320-350 | 350-380 | 380-410 | 410-440 | 440-470 | ||

| 32 | 340-390 | 370-420 | 400-440 | 430-470 | 470-500 | 500-510 | 530-540 | |||

| PYY500 | 25 | 300-350 | 330-380 | 370-420 | 400-450 | 430-480 | 460-510 | 500-550 | ||

| 32 | 500-550 | 550-600 | 600-650 | 650-700 | 700-750 | 750-800 | ||||

| 40 | 650-700 | 700-750 | 750-800 | 525-875 | 900-950 | 950-1000 | ||||

| Ukuran | |||||

|---|---|---|---|---|---|

| Model | A | B | C | D | E |

| PYY100 | 1320 | 1120 | 1550 | 2104 | 1620 |

| PYY200 | 1670 | 1320 | 1667 | 2645 | 2061 |

| PYY300 | 1850 | 1660 | 2046 | 2837 | 2210 |

| PYY500 | 2200 | 1700 | 2133 | 3133 | 2531 |

| PYYZ100 | 1310 | 1480 | 1686 | 2424 | 1704 |

| PYYZ200 | 1670 | 1530 | 1677 | 2645 | 2061 |

| PYYZ300 | 1850 | 1660 | 2046 | 2837 | 2210 |

| PYYZ500 | 2200 | 2400 | 2133 | 3600 | 2531 |