Submerged spiral classifier

The spiral classifier is widely used to pregrading and inspection grading in closed circuits when used in the production flow of metal processing. According to the difference in sedimentation rate of mineral particles and mud, the particle sizes of ores with 1.5mm-0.03mm are classified. Classification equipment—the spiral of overflow end is completely immersed below liquid level. An automatic elevating apparatus is added to the discharge opening. The scoop in ball mill is eliminated bringing more stable operation

Scope of Application : overflow particle size is 0.15 ~ 0.07 mm of ore

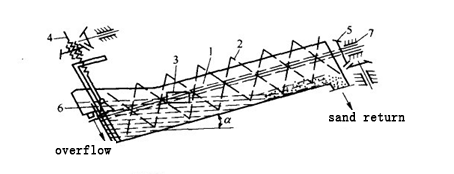

Principle

1. water channel 2. spiral 3.feed inlet 4. Spiral lifting device 5. Spiral gearing 6. downflow weir 7. Bearing

Fine ore pulps are fed into water tank through feeding opening located in the center of settling zone. Beneath the inclined water tank is the ore pulp classification zone where ore pulps are stirred by low-speeded impellers. Fine ore particles are lifted up and then spilled out the overflow opening; coarse ore particles precipitate down to tank bottom and are discharged via discharge opening

Advantages

Energy saving;

Increase the return sand sand back end automatic lifting device, unconfigure ball tablespoon head;

Per ton of ore can be saved 1 to 1.5 degrees;

Avoid maintenance tablespoon head frequently;

It slowed the uneven impact of the mill large and small gear.

Parameter

| Submerged spiral classifier | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Model | specification | spiral diameter(mm) | Spiral speed(r/min) | Flume | Production capacity(t/24h) | drive motor power(kw) | lifting motor power(kw) | |||

| length(mm) | width(mm) | obliquity(°) | overflow Volume | Sand return Volume | |||||||

| single-screw | FC-10 | Φ1000 | 1000 | 6-7.4 | 6500 | 1110 | 10.5°-14° | 75 | 473-1026 | 5.5 | |

| FC-12 | Φ1200 | 1200 | 5,6,7 | 8400 | 1372 | 10.5°-14° | 120 | 1170-1630 | 7.5 | 2.2 | |

| FC-15 | Φ1500 | 1500 | 2.5,4,6 | 10500 | 1664 | 14°-18.5° | 185 | 1140-2740 | 7.5 | 2.2 | |

| FC-20 | Φ2000 | 2000 | 5.4 | 12800 | 2396 | 14.5°-18.5° | 400 | 5940 | 18.5 | 2.2 | |

| FC-24 | Φ2400 | 2400 | 3.6 | 14130 | 2600 | 14°-18.5° | 455 | 6800 | 18.5 | 2.2 | |

| FC-30 | Φ3000 | 3000 | 3.2 | 14300 | 3200 | 14°-18.5° | 705 | 11650 | 30 | 4 | |

| double-screw | 2FC-12 | Φ1200 | 1200 | 6 | 8400 | 2620 | 14°-10.5° | 240 | 1770-2800 | 7.5X2 | 2.2X2 |

| 2FC-15 | Φ1500 | 1500 | 2.5,4,6 | 10500 | 3200 | 14°-18.5° | 370 | 2240-5360 | 7.5X2 | 2.2X2 | |

| 2FC-20 | Φ2000 | 2000 | 5.4 | 12800 | 4280 | 14.5°-18.5° | 640 | 7780-11880 | 18.5X2 | 2.2X2 | |

| 2FC-24 | Φ2400 | 2400 | 3.6 | 14130 | 5040 | 14°-18.5° | 910 | 13700 | 18.5X2 | 2.2X2 | |

| 2FC-30 | Φ3000 | 3000 | 3.17 | 14300 | 6300 | 14°-18.5° | 1410 | 23300 | 30X2 | 4X2 | |