Next

Water jet pump

The vertical sand unloading pumps are designed for delivering abrasive,particle and high- density slurries and applied over the fields such as metallurgy, mining, coal, power, building materials, and environmental protection.

Production capacity : 8.9—26.1 m³/min

Max vacuum degree : 96Kpa

Structure

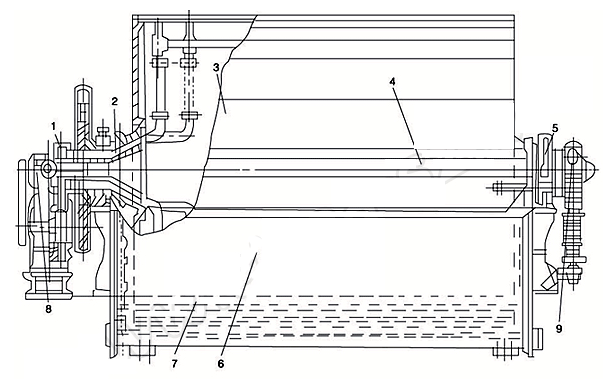

External filtration type drum vacuum filter consists of cylinder, transmission structure, allocation head, main shaft, agitation device, slurry tank, scraper and coiling device etc.

1.Left and right allocation head 2.Piping;3.Cylinder;4.Scraper;5. Main bearings;6.Slurry tank;7. Agitation device;8Transmission structure

Work Principle

The cylinder is main part of filter. The large size cylinder is made of welded steel plate, the small size made of cast cylinder, and some old-fashioned filter cylinder made of thick wood. The filter cylinder is divided to some filtering chambers by strip along the circumferential direction. These chambers are strictly sealed without ventilation between each other. Filter plate is laid on filter chamber forming a channel for filtrate and supporting filter cloth.

The cylinder is wrapped in filter cloth in order to ensure the sealing between each chamber.

There is a pipe at one end of the cylinder body which has the same number of channels with chambers.Each channel connects with corresponding filter chamber. The transmission mechanism drives the cylinder, and could transform several speeds.

Advantages

1.Adopts advanced technology to design and manufacture,having long service life.

2.The equipment and operation is simple and easy.

3.Improved upon the basis of similar products by our company.

4.High efficiency and low cost.

5.Wear resistant wet parts which are made of hard metal (Chrome alloy).

6.Long bearing life: The bearing assembly is with large diameter shaft and short overhang