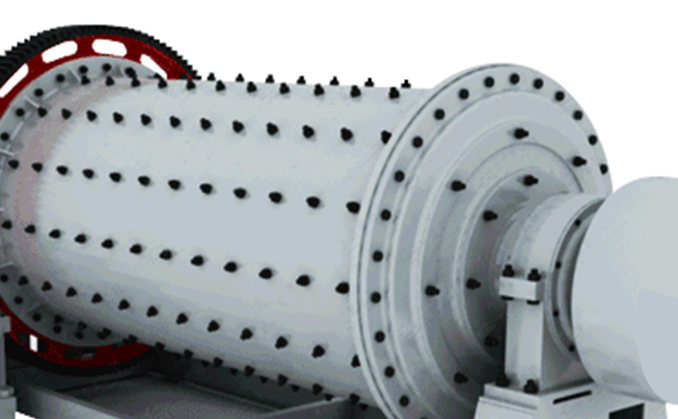

Wet overflow ball mill

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding.

Production capacity : 0.17~170t/h

Effective volume : 0.9-78m³

Structure

It is mainly composed of feeding, feeding, main bearing, cylinder, transmission department, delivery department and the main motor and other parts.

The main component of wet overflow ball mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill.

Advantages

1. The jack-up device of wet grate ball mill makes maintenance easy.

2. The hydrostatic and hydrodynamic bearings ensure the smooth operation of wet grate ball mill.

3. The low speed transmission of wet grate ball mill contributes to easy overhaul and maintenance.

4. The oil-mist lubrication device guarantees reliable performance of bearings.

5. The gas clutch adopts the flexible start-up model

Parameter

| Wet overflow ball mill | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | barrel | Motor | Boundary dimension | Effective volume(m3) | Max loading ball(t) | weight(kg) | |||||

| diameter(mm) | length(mm) | speed(r/min) | Model | power(kw) | length | width | height | ||||

| MQY0918 | 900 | 1800 | 39.2 | Y225M-8 | 22 | 4196 | 2336 | 2015 | 0.9 | 1.66 | 5340 |

| MQY1212 | 1200 | 1200 | 31.3 | Y250M-8 | 30 | 4500 | 2104 | 1733 | 1.1 | 2.4 | 11438 |

| MQY1224 | 1200 | 2400 | 31.3 | Y280M-8 | 45 | 5764 | 2104 | 1733 | 2.4 | 4.6 | 13200 |

| MQY1515 | 1500 | 1500 | 30.9 | JR115-8 | 60 | 6094 | 2743 | 2170 | 2.5 | 5 | 13120 |

| MQY1530 | 1500 | 3000 | 30.9 | JR117-8 | 80 | 6800 | 2743 | 2170 | 5.08 | 8.6 | 19166 |

| MQY1545 | 1500 | 4500 | 30.9 | JR127-8 | 130 | 9085 | 3091 | 2170 | 6.57 | 11.3 | 22147 |

| MQY2122 | 2100 | 2200 | 24.05 | JR128-8 | 155 | 7750 | 4450 | 3533 | 6.6 | 16 | 42500 |

| MQY2130 | 2100 | 3000 | 24.05 | JR137-8 | 210 | 8330 | 4450 | 3533 | 9 | 20 | 44260 |

| MQY2145 | 2100 | 4500 | 24.05 | JR137-8 | 210 | 9933 | 4450 | 3533 | 13 | 23.5 | 50348 |

| MQY2430 | 2400 | 3000 | 22.5 | JR138-8A | 280 | 8823 | 5113 | 3894 | 12.1 | 22.5 | 58328 |

| MQY2436 | 2400 | 3600 | 22.5 | JR138-8B | 320 | 9455 | 5113 | 3894 | 14.5 | 26 | 61308 |

| MQY2727 | 2700 | 2700 | 21.6 | JR138-8B | 320 | 8643 | 5722 | 4674 | 15.3 | 30 | 83145 |

| MQY2736 | 2700 | 3600 | 21.6 | JR1510-8 | 400 | 10463 | 5942 | 4674 | 18.4 | 34 | 89120 |

| MQY2745 | 2700 | 4500 | 21.6 | TDMK450-32 | 450 | 11471 | 5907 | 4674 | 23 | 42 | 109318 |

| MQY3236 | 3200 | 3600 | 18.5 | TDMK630-36 | 630 | 12442 | 7030 | 5150 | 25.6 | 51 | 144241 |

| MQY3245 | 3200 | 4500 | 18.5 | TDMK630-36 | 630 | 13975 | 7030 | 5150 | 32.8 | 61 | 153390 |

| MQY3254 | 3200 | 5400 | 18.5 | TDMK1000-36 | 1000 | 14875 | 7030 | 5150 | 39.5 | 73 | 163760 |

| MQY3645 | 3600 | 4500 | 17.3 | TDMK1000-40 | 1000 | 15200 | 7680 | 5463 | 41 | 76 | 174700 |

| MQY3650 | 3600 | 5000 | 17.3 | TDMK1250-40 | 1250 | 15700 | 7680 | 5463 | 46.4 | 86 | 178000 |

| MQY3660 | 3600 | 6000 | 17.3 | TDMK1250-40 | 1250 | 16910 | 7680 | 5463 | 55.7 | 102 | 198000 |

| MQG4067 | 4000 | 6700 | 16.2 | TDMK1800-30 | 1700 | 17400 | 9600 | 7300 | 78 | 138 | 240000 |