Wet road mill

Wet rod mill is mainly used for coarse grinding. It is configured for fine and coarse grinding in the first stage open-circuit grinding, especially suitable for brittle ore materials.

Production capacity : 0.62~250t/h

Scope of Application : Mainly used for coarse grinding operations

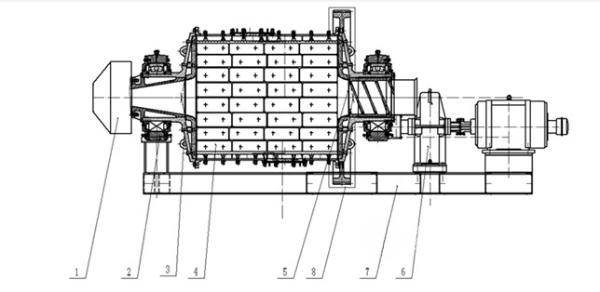

Structure

1. feeding device 2. Bearing 3. feed inlet 4. Barrel 5. discharge hole 6. Power Train 7. Rack 8. Gear cover device

The main component of wet rod mill is a cylinder with bigger diameter and smaller length which is revolved by transmitting machinery. Materials are put in cylinder through the feed opening and then thoroughly grinded. The falling course of iron balls and ores can produce huge falling impact and autogenous grinding. The continuous feeding of ores can create considerable pressure to make ores move from feed opening toward discharge opening. Finally, acceptable particles are discharged from the discharge opening. Acceptable ore particles are carried away by water by wet mill, or by air by dry mill.

Advantages

1. Iron rods can move inside mill with regularity.The curvature of end cover of wet rod mill is relatively small, which renders iron rods move inside mill with regularity.

2. Easy installation and maintenance.

3. Quick discharging.The diameter of discharge hollow shaft is comparatively bigger, which makes overhaul easier and diminishes the liquid level of ore pulp. Consequently, discharge becomes faster.

4. Uniform ore particles.

5. Low incidence of overly grinding.Uniform ore particles. Less incidence of overly grinding.

Parameter

| Wet rod mill | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | barrel | Motor | Boundary dimension | Effective volume(m3) | Max loading ball(t) | weight(kg) | |||||

| diameter(mm) | length(mm) | Model | power(kw) | speed(r/min) | length | width | height | ||||

| MBY 0918 | 900 | 1800 | Y225M-8 | 22 | 730 | 4980 | 2370 | 2020 | 0.62~3.2 | 0.9 | 5700 |

| MBY 0924 | 900 | 2400 | Y250M-8 | 30 | 730 | 5670 | 3280 | 2020 | 0.81~4.3 | 1.2 | 5880 |

| MBY 1224 | 1200 | 2400 | Y280M-8 | 45 | 730 | 6450 | 2800 | 2500 | 0.4~4.9 | 2.28 | 12308 |

| MBY 1530 | 1500 | 3000 | JR125-8 | 95 | 725 | 7935 | 3185 | 2280 | 0.4~4.9 | 5 | 19990 |

| MBYg 1530 | 1500 | 3000 | JR117-8 | 80 | 725 | 7253 | 3070 | 2280 | 2.4~7.5 | 5 | 21210 |

| MBYg 2130 | 2100 | 3000 | JR136-8 | 180 | 735 | 8122 | 4220 | 3073 | 14~35 | 9 | 42123.5 |

| MBYg 2136 | 2100 | 3600 | JR137-8 | 210 | 735 | 8958 | 4320 | 3025 | 43~61 | 10.8 | 45800.5 |

| MBYg 2430 | 2400 | 3000 | JR138-8 | 280 | 735 | 9005 | 4836 | 3490 | 43~61 | 11.5 | 55795 |

| MBYg 2732 | 2700 | 3200 | JR157-8 | 320 | 750 | 10509 | 5000 | 3620 | 43~61 | 15.7 | 83110 |

| MBYg 2736 | 2700 | 3000 | JR158-8 | 380 | 743 | 10764 | 5750 | 3620 | 32~86 | 17.7 | 90441 |

| MBY 2740 | 2700 | 4000 | TDMK400-32 | 400 | 187.5 | 12300 | 5700 | 4700 | 43~110 | 20.4 | 75000 |

| MBY 3040 | 3000 | 4000 | JR1510-8 | 570 | 740 | 9800 | 3900 | 3900 | 54~135 | 26 | 90000 |

| MBY 3245 | 3200 | 4500 | TDMK800-36 | 800 | 167 | 14600 | 7000 | 5300 | 64~180 | 31 | 113000 |

| MBY 3645 | 3600 | 4500 | TDMK1250-40 | 1250 | 150 | 15200 | 8800 | 6800 | 80~230 | 41.8 | 139000 |

| MBY 3654 | 3600 | 5400 | TDMK1600-40 | 1600 | 150 | 15900 | 8800 | 6800 | 100~250 | 49.7 | 150000 |