Next

XJ Flotation machine

Flotation cell machine is applicable for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and floatation, so the useful ore are reclaimed.

Production capacity : Flotation cell machine is applicable for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry, which are subject to coarse separation, swept separation, fine separation and floatation, so th

Applicable material : Black metal minerals, TongQianXin gold and other

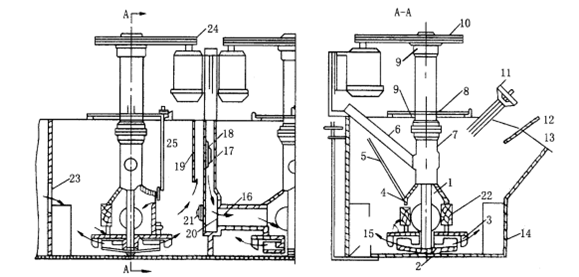

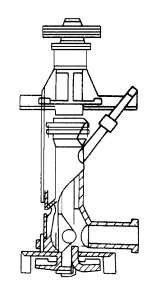

Structure

1. principal axis 2. Impeller 3. cover board 4. joint pipe 5. Sand hole lock screw 6. intake-tube 7. Tracheal tube 8. riser plate 9. Bearing 10. belt wheel 11. overflow valve hand wheel and screw 12. scraper blade 13. Bubble overflow mouth 14. cell body 15. Put sand gate 16. Feed tube 17. overflow weir 18. bypass damper 19. outer wall of the gate 20. sand hole 21. Sand hole gate 22. Middlings Return to the hole 23. downflow weir of Dc slot 24. Motor and pulleys 25. Circular hole adjusting lever

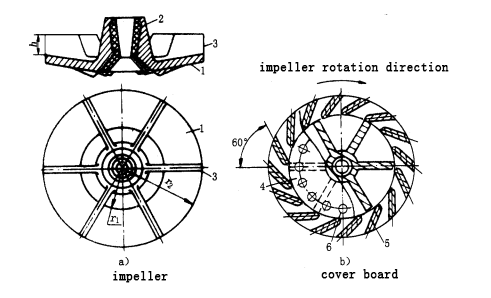

1. Impeller conical chassis 2. Stock 3. Radiation blade 4. cover board 5. stator vane 6. circulation port

R1– Pulp inlet radius R2– lp export radius h—blade external height

Flotation cell machine has the advantages of large air-absorption capacity and low energy consumption. Every cell owns three functions: air absorption, slurry absorption, and floatation separation, and the cells form a floatation separation loop by itself without any auxiliary equipment, and is allocated horizontally, which favors the change of flow. The circulation of mineral slurry is reasonable, and can avoid the disposition of coarse sand to the largest extent. There is self-control device on the surface of mineral slurry, so it is easy to adjust it. The impeller has backward-inclined upper and lower vanes, which produce upper and lower circulation of mineral slurry respectively.

Working Principle

1. when flotation machine works, slurry is inhaled from the bottom of the trough to the space between impellers

2. Meanwhile, the low pressure air send by fan is sent to this area through the air distributor in the hollow shaft

3. After sufficient mixing, the slurry is pushed out by the impeller, and then goes to the whole trough

4. When the froth rises to the stable level, after the enrichment processing, froth overflows to the froth through from the overflow weir. Another part of ore slurry flows to lower part of impeller for the remis with air

5. The remained slurry flows to the next trough until becomes residue

Advantages

Aerator

1, Rich experience

2. Reliable quality

3. Reasonable price

4. Durable components

5. Suitable for many requirement

Parameter

| XJ Flotation machine | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Model | Effective volume(m3) | Production capacity(m³/min) | Impeller diameter(mm) | Impeller speed(r/min) | Motor Power(kw) | Single tank weight (kg) |

|||

| agitator | scraper blade | ||||||||

| XJ-1 | 0.13 | 0.05-0.16 | 200 | 600 | 1.5 | 0.55 | 320 | ||

| XJ-2 | 0.23 | 0.12-0.28 | 250 | 504 | 3 | 390 | |||

| XJ-3 | 0.35 | 0.18-0.4 | 300 | 483 | 1.5 | 0.75 | 430 | ||

| XJ-6 | 0.62 | 0.3-0.9 | 350 | 400 | 3 | 1.1 | 860 | ||

| XJ-11 | 1.1 | 0.6-1.6 | 500 | 330 | 5.5 | 1635 | |||

| XJ-28 | 2.8 | 1.5-3.5 | 600 | 280 | 11 | 2430 | |||

| XJ-58 | 5.8 | 5-7 | 750 | 240 | 22 | 1.5 | 3633 | ||